There has been a lot of discussion in the media about the impact advanced robots will have on future human employment. Part of this discussion has moved into the field of advanced AI and how it may impact employment in non-manual labour areas.

We have been using robots in manufacturing for years, particularly in processes that are either repetitive or in environments that are not conducive to human occupation. Similarly, AI has been around for several years. One notable property of AI that has been used extensively has been that of pattern matching. The Post Office has been using AI successfully in their sorting centres for a long time, however, we have moved on a long way from simple pattern matching algorithms to much more sophisticated decision making and self-learning systems of advanced AI.

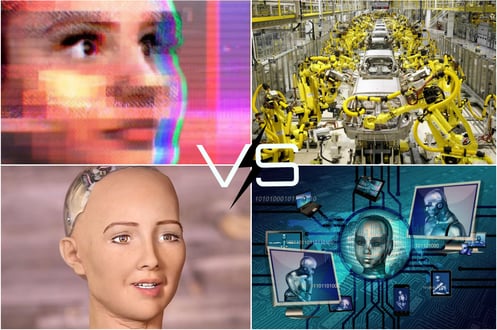

Advanced Robots vs Advanced AI: Impact on the Process

It is these areas where advanced AI and processes may start to develop conflict. By definition, AI will make decisions based on both the information available to it and the heuristics for the decision making programme it is based upon. The logic it will employ to make decisions will generally be modified from its ability to learn as it progresses (very much like a human does). Therefore, whilst advanced robots can now perform a wider range of tasks then ever before, they can perform the same operation over and over again with more or less the same output - depending on factors such as the variability of the inputs and degradation of any of the robot’s mechanical structure - with today's AI, decisions may be made that change the outputs, making processes less repeatable.

AI vs robotics

AI vs robotics

Of course, one way around this would be to define what is a successful outcome for the AI entity, but then why go to the expense of incorporating AI into a system when a robotic system would produce the same result. So where does AI fit into a process driven operation? The answer to that lies in thinking of a process that transforms given inputs into required outputs. If you do not care how the transformation takes place - or the variability of the inputs may be such that a lot of decision making needs to take place during the process to achieve a consistent output - then AI could be a suitable solution. An example of this would be in a potato packing plant. Potatoes come in all shapes, sizes and weights and need to be packed into standard packages weighing a set weight within a lower fixed tolerance. You could put more weight in the package but then you would be losing money. An advanced AI solution could be employed to ensure all packages reach the minimum weight without going too far over weight. From the company perspective, how it manages to optimise the packaging of the whole potatoes is not a major concern.

The Future of Advanced AI and Advanced Robots

The big question becomes one of how will advanced AI impact the way processes are carried out in the future? My experience has been that a lot of processes are described in a very procedural way. By that I mean each step is set out to be followed to ensure repeatability. This is great when working with advanced robots; however, when you combine the robot with the ability to make decisions based upon circumstances and then add the ability for it to learn from past experience you have an AI machine that may or may not follow the prescribed steps. In these circumstances we will need to consider that processes become more of a ‘black box’ with the outcomes of the processes being carefully described, together with the tolerances on the outcomes and the constraints that need to be put in place for the process and not worry about how the outcomes are arrived at by the AI machine. In other words, process descriptions become more about the objectives of the transformations of the inputs than the way the transformations are carried out.

The future is here, make sure you keep up-to-date by signing up for the  ...

...

Related Articles

BPM 2018: Top 10 BPM Industry Trends for the Year

The Construction Industry's Efficiency Curse Needs Digital Transformation

20 Business Improvement Experts Give Their Golden Rule For Success

Written by Terry Giles

Terry Giles is a consultant for TerryAG Consultancy. He has a great deal of experience in developing Business Management Systems based around a variety of models including ISO 9001, TL 9000, ISO 14001, EFQM, Baldrige, CMMi, ITIL, RiskIT and CobiT 4.1 & 5.