How much change is too much change? During my time as a Quality Professional this question has been one I have struggled with.

On the one hand continuity of a process will lead to a consistent output, however section 10.3 of ISO 9001:2015 extols us to continually improve the suitability, adequacy and effectiveness of the quality management system.

Which whilst not stating that we must change for the sake of changing, it does put an onus on management to be open to changes that improve the way the organisation works.

The trap unfortunately is that it can also be misinterpreted to be a call to embrace change for the sake of change.

Change can be both positive and negative

One of the great benefits of mapping processes is that it promotes consistency in the way we work.

A consistent way of working is one of the key components in producing a consistent product. If the quality of the product is also acceptable, then there appears no reason to change anything.

Unfortunately life is not that simple, as your competitors are also trying to improve their market share by either producing a superior product or by reducing their costs so they can sell cheaper.

Therefore change is inevitable.

One of the drawbacks with change is that it will cause disruption to the ways we work and therefore risks degrading the product. The problem then becomes one of deciding what type and level of change is required to either maintain or improve your position in the market place.

In addition focusing on just the change and the localised effects of that change may risk degrading competitiveness by either compromising something down the line or by increasing the cost of production.

A good example of this occurred in a company I worked for, where a team on a production line came up with a quicker way of assembling a sub-assembly (a unit assembled separately but designed to be incorporated with other units into a larger manufactured product) using a quality circle.

Unfortunately the next stage in the production line could not handle the increase in production and stocks of the sub-assembly built up. The answer could have been to look at how to increase the rate of assembly of the next stage to fully utilise the increase in sub-assembly production. The problem with this was that the rate of production of the final assembly was more than capable of meeting customer demand. Therefore an increase in production would have meant increased stocks in the warehouse and hence increased costs for the company. So in fact, a positive change at a local level resulted in a negative change at the macro level.

Understanding the impact of change

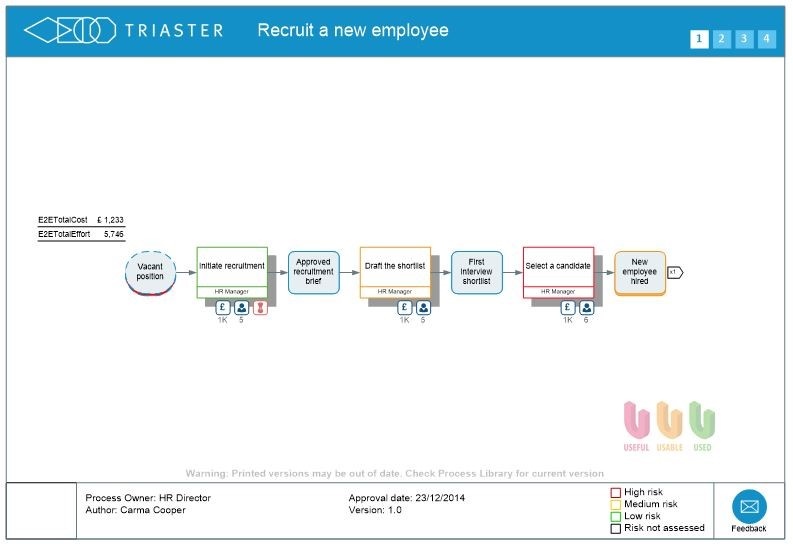

Understanding the end-to-end processes and being able to model how a change in any part of the process can affect the overall outcome, is key to ensuring that when changes are implemented, the overall effect on the business is positive.

All change will have both short and long term effects on the business, investigating the effects of changes across the business is vital for ensuring successful change management. Knowing what your business processes are and how they join together (outputs into inputs) allows for that modelling to be carried out prior to implementation.

For some help with how to understand the end-to-end processes, please download the white paper: Successful Process Mapping.

Related Articles

Business Process Improvement: Understanding the Impact of Change

Becoming an Organisational Change Guy or Change Lady

How to Create a Successful Business Process Improvement Model

How do I create a culture of Continuous Improvement?

How to Improve Business Processes...Before You Know What They Are

Written by Terry Giles

Terry Giles is a consultant for TerryAG Consultancy. He has a great deal of experience in developing Business Management Systems based around a variety of models including ISO 9001, TL 9000, ISO 14001, EFQM, Baldrige, CMMi, ITIL, RiskIT and CobiT 4.1 & 5.