When trying to implement Lean continuous improvement projects, quality managers often ask themselves how to cut waste effectively in their organisation. Unsurprisingly, wasteful processes may slow down efficiency - consequently costing a business time and money.

The problem is that change can be just as harmful, maybe even more so than continuing the current process, if that change is not implemented correctly (which is why process modelling is so useful). Reducing waste and creating a lean organisation can be successful, if handled carefully and correctly.

Creating a Lean Organisation With Lean Continuous Improvement

Lean continuous improvement projects are all too often carried out by cutting back on something that looks wasteful without really understanding the impact. This can mean that something is cut that results in additional costs elsewhere - which far outweigh the initial savings.

Here are some ways to reduce waste, create lean organisations and get the answers on how to stop wasting money in your business

1. Really Understand How Your Business Works

Businesses and organisations are complex. It is this complexity that leads to businesses wasting money. Inefficiency can creep in, in so many ways:

- Inconsistent working

- Inaccurate working

- Duplication

- Production of redundant outputs

These are just a few examples. If only a small amount of money is wasted each time, as this is repeated, the costs mount up.

The only way to identify these inefficiencies is to really understand what is done in your business or how it works.

The best way to do this is to adopt a process management approach.

Every organisation has processes. Every organisation needs a way of understanding the value that process delivers to your organisation (process map) and every organisation needs to know how to model improvements and implement them effectively (Business Process Management).

Below, I have outlined exactly what a process is, what a process map is and what Business Process Management is to give greater understanding to organisations on how to understand and implement lean continuous improvement and create a lean organisation.

What is a Process?

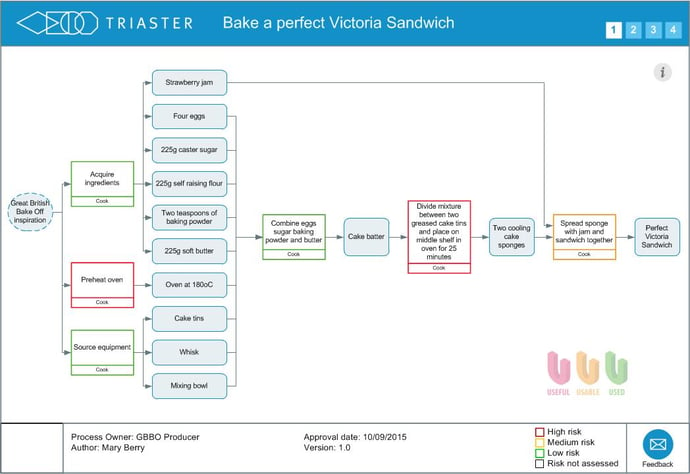

A process is a series of actions or steps taken in order to achieve a particular end. A process is a transformation. It transforms inputs into outputs. For example, a process is the mechanism by which raw materials are converted into products, so baking a cake will involve taking various ingredients (inputs) and producing the cake (output) using the recipe (process).

Processes are best captured in a process map.

What is a Process Map?

A process map sets out in diagrammatic form the activities that transform inputs into outputs.

It is very visual way of representing how your business works.

Whilst process mapping can be done just using a process mapping tool, rather than a full business process management system, the resulting maps (of which there will be several hundred) will be hard to manage.

What is a Business Process Management (BPM) System?

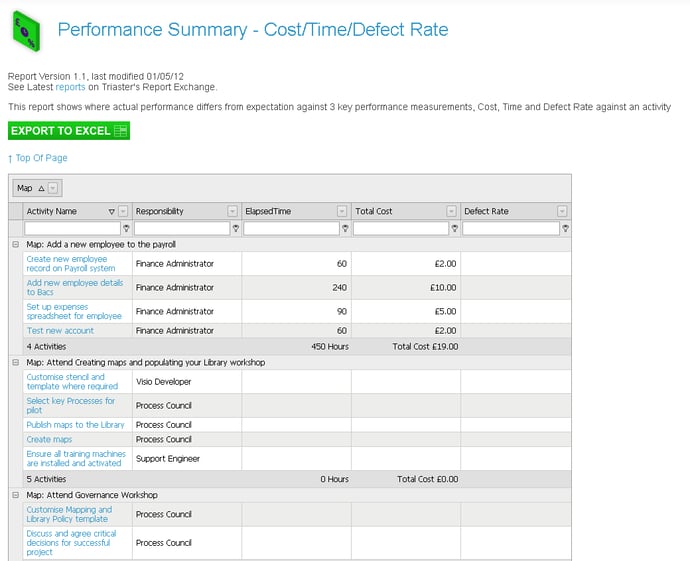

This is a system that both enables you to easily capture your processes as process maps and also intelligently houses, manages and reports on them, allowing you most easily identify where to save money.

It is not a quick job to capture all the end-to-end processes in a business, so it is best to start with an area of the business which is believed to be inefficient and process map that in the first instance.

Alternatively, start with a process that is repeatedly performed – small efficiency gains in these processes quickly result in a lot of money saved.

In the past years, the rapid rise of cloud computing has also reached Business Process Management - so, these days, many business owners also consider getting started with a cloud-based rather than on-premises BPM system. If you're interested in the possibilities of cloud-based BPM systems, feel free to learn more here:

2. Focus on the Outputs

As we have seen, a process is a transformation, it transforms Inputs into Outputs. And it is the Outputs that really count.

It is very easy for all of us to spend every day busy doing things, but if we aren’t producing anything – there is no Output – it is very likely that what we are doing is wasteful. This is very quickly picked up when actually doing the process mapping; keep asking the question - what is produced?

3. Ask the Person Who Does the Job

Whilst the person who does the process mapping doesn’t need to be the person who does the job, their input is really important. They, more than anyone, will know where the inefficiencies are and often are just waiting to be asked about them. They are also likely to have some pretty good ideas about what should be changed to make the process more efficient – and save money.

4. Look at the Handover Points

This is often where the most business waste arises. One department produces something and it is not quite in the format that the receiving department needs it, so it needs to be reworked to make it useful. Or the receiving department no longer use it at all! E

Even though effective lean continuous improvement may take some time, once inefficiencies are picked up at the process handover points, and once addressed, the changes made can immediately start to save money.

5. Look for the Bottlenecks

If something is waiting to be dealt with at a pinch point or bottleneck, then it’s not delivering any value during all that time. Ask where the bottlenecks are - so that they can be tackled first.

Lean organisations are exceptional at finding the steps in a process that aren't delivering any value. If you find these and fix them appropriately, then you'll be surprised at how effective your lean continuous improvement project is in addressing and cutting out waste quickly.

6. Involve the Person Who Owns the Process

The Process Owner is the person who has the authority to change a process. Involve them in the process mapping, and then if a change is to be made, they can say then and there that it is approved.

7. Implement Best Practice

Very often the same process is delivered in different ways in different parts of the business. Once the correct process is captured (the correct process as it looks right now), the best practice process – the one which is most efficient – can be identified and adopted throughout.

8. Capture Key Data at the Process Level

Using a BPM system which allows a business to capture and report on key data at the process level (attach data to the shapes in the process maps) is so valuable to a lean organisation. This allows less obvious inefficiencies to be identified and addressed. It also enables you to quantify just how much money has been saved.

9. Model Potential Improvements

Once you have a process model of how your organisation currently works, this is the start point for modelling future options. Your BPM system should allow you the capability to model different scenarios for improvement, enabling you to understand the impacts before they are made. Thereby avoiding a great deal of upheaval with no money saved.

10. Continually Look for Ways to be More Efficient

Identifying inefficiencies should not be a one-off exercise, but a continual exercise of looking at what you currently do and improving it. This is the key to lean continual improvement. You won't have a perfect organisation after the first process changes are made, but with a continual focus on continually improving processes, you will have an ongoing increase in quality, customer satisfaction and efficiency.

If you want to dive a little deeper into lean continual improvement and want to know what it takes to be a lean organisation; take a look at the  , which shows how 8 companies went from process problems to continual lean improvement.

, which shows how 8 companies went from process problems to continual lean improvement.

Related articles:

What are the 7 Wastes That are Killing Business Efficiency?

How this Successful Process Mapping Example Resulted in £350k ROI [Infographic]

How Cloud BPM Creates Business Process Improvement Opportunities

Written by Emma Harris

Emma was Operations Director for Triaster for nearly 20 years, during which time as well as learning and perfecting her BPM and process improvement skills, she honed her inbound marketing expertise. She now runs D2e - Designed to engage - which designs and develops bespoke, engaging, HubSpot CMS websites, that help your entire company to grow and scale. She is delighted to still be delivering Triaster's marketing, whilst also helping other companies turn their websites into their hardest working asset.