In researching this article, we analysed 20 companies that have been extremely successful in implementing business improvement and found that there are 10 actions that they all took to create success from start to finish.

The 10 approaches that these companies all took are set out below. It is important to highlight however that none of these improvement steps live in isolation. For long lasting, impactful business improvement, each of these actions need to be harnessed at different stages of an overall plan.

- Create an 'Operational Excellence Group'

- Develop an Implementation Action Plan

- Ensure Key Stakeholder Engagement

- Implement a Single Management System that is Useful, Usable and Used

- Employ a Many-stranded Communications Plan

- Use an Easy-to-understand Business Improvement Methodology

- Capture the Current 'State of Affairs'

- Establish Consistent Best Practice

- Make Any Large Scale Changes Shareable and Accessible

- Practice Continuous Improvement

10 Business Improvement Techniques Successful Businesses Have in Common

1. Create an 'Operational Excellence Group'

One of the common factors in successful business improvement is a specific 'task force' created to drive the business improvement project.

Setting up regular meetings and integrating the right team members is key to engaging those required to bring about improvement.

Regardless of whether you are a small or large organisation, setting up an Operational Excellence Group, has huge benefits when driving a the change initiative.

National Oilwell Varco set up an 'Operational Excellence Group' for process and flow technologies. They quickly realised that their challenge was not only a practical one, but a cultural one as well and extended the scope of their project to also addressed this.

2. Develop an Implementation Action Plan

Stating this isn't going to win any awards for originality, but most improvement projects live and die in the planning stage. In order to be ready for implementation, a company must:

- Identify what the Problem is

- Identify what needs to change

- Identify what the organisation needs to make that change a success

- Research, tailor and compare the necessary tools/methodologies/software companies that fit the business

- Consider whether you have the time/resources to really make your implementation successful - if you don't then you shouldn't begin in the first place.

When initially creating their action plan, Skanska UK identified three changes that would revolutionise the way they ran their business.

They would implement:

- One management system containing policies, processes and procedures common to all operating units

- A single accreditation (LRQA)

- A common business process management platform

After listing areas of their business, Skanska UK were immediately able to identify that all of their processes fell into one of these categories:

- Functional Area – supporting processes, health and safety, procurement

- Project Control – everyday project management processes

- Sector – processes to meet specific requirements e.g. gas, highways etc.

This gave them the structure and the vision to know what had to be done and what they needed to achieve real change, which resulted in Skanska UK winning a British Quality Foundation UK Excellence Award.

3. Ensure Key Stakeholder Engagement

Whether or not a business improvement initiative is successful is more often that not determined by whether it is supported by a change to the culture of the business. Accordingly many of the 10 approaches taken by those companies most successful at business improvement are to enable and support cultural change.

None is more important than ensuring key stakeholder engagement. Your success is dependent on gaining buy-in from senior management and key stakeholders right from the start. If they don't visibly support your business improvement initiative, no one else in your organisation will.

4. Implement a Single Management System that is Useful, Usable and Used

Many companies implement a Business Management System, which doesn't help them achieve business improvement. Sometimes it just there to tick a box or perhaps get an accreditation. However successful businesses, recognise how important their BMS can be in enabling business improvement and choose one that:

- Supports their specific objectives and requirements

- Is user friendly and flexible, helping to enable cultural change

- Easily accessible by all members of staff

- Delivers a single, standardised source of process control that provides uniformity, clarity and consistency at all times.

The team at Homeserve needed a Business Process Management Solution which would support them to easily map their customers' journey and enable all staff to see and best understand their end-to-end process.

The team's core requirement was a central source of information that all staff could easily access, to view the entire customer journey and find the information - processes, policies, scripts and forms - that they need to do their job. The aim was to ensure that all customers receive the same level of effortless experience, regardless of whoever they spoke to.

With Triaster they found a management system that would enable them to upload new scripts for colleagues, provide easy navigation, colours and illustrations to provide a better user experience and process flows that were easy to understand and supported consistent business outcomes.

5. Employ a Many-stranded Communications Plan

Another key approach in achieving cultural change is letting everyone know what you are working to achieve and most importantly, why. This takes more more focus and work than perhaps might be expected. You can't just explain it to everyone once and assume they have all taken it on board. Information needs to be explained multiple times and in multiple ways; cultural change most definitely takes a many stranded communications plan. Triaster customers have successfully supported business improvement initiatives with launch events, training days, stationary, posters (you name it) to support their business improvement projects.

The most successful improvement projects we surveyed documented that continually hosting follow-up events every 3-6 months will make sure that your employees know that the new initiative is here to stay, so they better get up to speed.

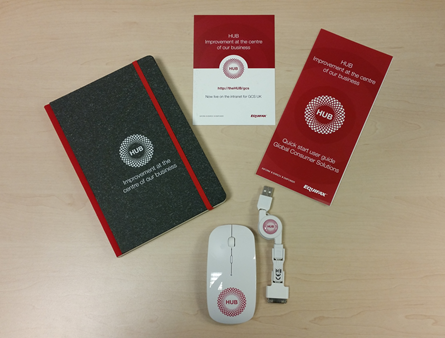

When Equifax launched their Process Library, they gave it a great name, 'HUB' and brand and supported it's launch with events, printed materials and branded giveaways.

6. Use an Easy-to-understand Business Improvement Methodology

You might have time to learn a complex improvement methodology if you are part of the operational excellence group but the more people who are involved with the change, the more people you will have to communicate change to.

People are all different. They come with their own unique backgrounds, differing technical knowledge and different prejudices. It is necessary to use an improvement methodology that can be mostly communicated without too much trouble or jargon (their pickup must be as effortless as your put down).

Take a look at our Noun-verb process mapping methodology for a better understanding of what a simple process mapping methodology looks like.

7. Capture the Current 'State of Affairs'

In order to make any meaningful change, you will need to know what the process looks like currently. Then you will be able to identify if there are any major process breakdowns and if the stakeholders have any ideas on where the process can be improved. That leads to subsequently creating a consistent 'best practice' for all future employees who carry out that task.

Creating process maps has always been at the front line of successful improvement initiatives but standardising their use and getting buy-in within the organisation has always been the trench standing in the way of the open pastures of operational excellence.

In 2012, Lockheed Martin UK Ampthill had their processes and controls in text-based documents. There were a great many documents spread across various Networks, some of which were in the United States (USA) and some of which were specific to the Ampthill site in the UK.

This was a big job, so the process and compliance team needed to:

- Identify exactly which documentation was relevant to the Ampthill site and prioritise it for process mapping

- Create a 'Process Library' which would be a 'one-stop-shop' for all policies, processes and procedures

- Create maps that would be an easy to understand visual representation of their processes

- Create maps that would contain process linkages and interactions which would be both visible and easy to follow (end-to-end business processes)

8. Establish Consistent Best Practice

Your company's ability to improve continuously relies on your employees' abilities (both individually and corporately) to get on board with the new program and consistently implement any best practice agreed upon programme.

When Sungard Availability Services created their Process Library 'ASK PAT' they had the aim of reducing errors, risks and supporting the provision of a standardised practice from within the organisation to deliver a more consistent standard of service for Sungard’s customers. Having a single target operating model has also opened the doors for Sungard AS to a single ISO20000 Certification across the USA, India and the UK.

Because of their standardised system within an easily accessible Process Library (ASK PAT), Service Management continually benefit from a clear definition of the process to provide new hardware and staff expectations can be set according to the performance expectations on the service.

Having all the processes, policies and work instructions in ASK PAT now allows Sungard AS to specify requirements and standards for consistent use across the business - with the agreement of stakeholders.

9. Make Any Large Scale Changes Shareable and Accessible

As already mentioned, your business management system should be your business' single source of accessible information. Some of the most successful businesses we have worked with have chosen to open their management system up to customers or even create cross-functional, cross-organisational management systems that can allow communication not just within the organisation, but to flow back in from without as well.

Interserve's problem was process accessibility. Interserve needed their team to have access to a single management system that was Standardised with best practice tools, templates and processes that simplify and improve the way in which Interserve mobilise their contracts.

Interserve’s Defence Team also shares their Process Library with their customer: the Ministry of Defence. The MOD were able to view their supplier’s processes and also shared their own with Interserve. Processes are now not only cross-functional but also cross-organisational.

10. Practice Continuous Improvement

The end of any business improvement initiative should always be the start of the next one. The newly implemented change becomes business as usual and the next most impactful business improvement initiative should get started. Continuous Improvement is how businesses stay successful over the long term.

Help Moving Forward

Triaster's Process Library is a useful and usable Business Management System, which is many successful companies use to support their Continual Business Improvement. If you are interested in business improvement techniques, have a look at it now:

Related Articles:

How To Process Map For Free with Process Navigator

Establishing a Business Improvement Team: 4 Must Do Actions

Business Process Improvement: Stop Struggling, Start Doing

Related White Papers & Case Studies

The Complete Guide to Continuous Improvement in Business

Triaster: Lifting the lid on the Triaster BMS

Case Studies: Real business improvement success stories from our customers

This is an updated and refreshed edition of an article originally written in 2017.

Written by Emma Harris

Emma was Operations Director for Triaster for nearly 20 years, during which time as well as learning and perfecting her BPM and process improvement skills, she honed her inbound marketing expertise. She now runs D2e - Designed to engage - which designs and develops bespoke, engaging, HubSpot CMS websites, that help your entire company to grow and scale. She is delighted to still be delivering Triaster's marketing, whilst also helping other companies turn their websites into their hardest working asset.