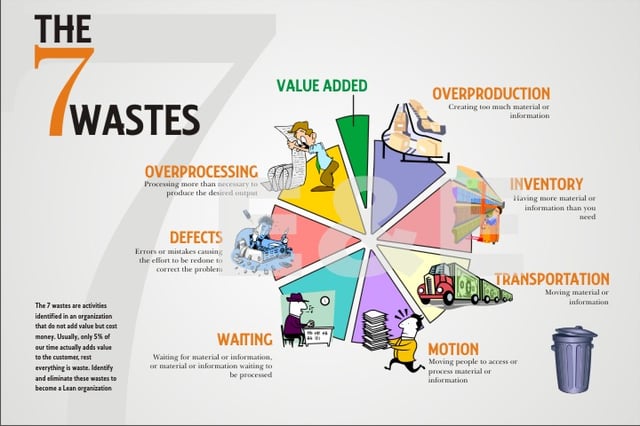

The 7 wastes are business activities which increase costs, but do not add value. It is estimated that only 5% of our time actually adds value to the customer; if this is indeed true, it means that every organisation can learn from the 7 wastes to improve business efficiency. In this article, I explore the 7 waste of Lean manufacturing and how to identify and cut out wasteful activities in your organisation.

This article covers:

- 7 Wastes of Lean Manufacturing

- The 7 Types of Waste Explained

- How to Identify the 7 Wastes in your Organisation

- How to Cut Out Waste in your Organisation

The 7 Wastes of Lean Manufacturing

The 7 wastes in Lean manufacturing can best be remembered through the acronym TIMWOOD. They are:

- Transport

- Inventory

- Motion

- Waiting

- Overproduction

- Over Processing

- Defects

Image from http://quotesgram.com/quotes-on-waste-lean/

From a process improvement perspective, these 7 types of waste are an invaluable tool, because simply by reducing them, one is invariably able to improve process efficiency.

The problem of improvement therefore becomes not one of ingenuity and creativity (to identify new and better ways of doing things), rather, it is more one of accurate identification of wasteful activities and identifying the way they are killing business efficiency.

The reduction of wasteful activities inevitably leads also to a corresponding increase in the proportion of value-adding activities, and the more visible the value-adding activities become, the easier it is to then keep improving the process.

(The proportion of value-adding activities in a process is referred to as the Process Cycle Efficiency, a key metric in Lean thinking to help understand if a process change is a process improvement.)

Over time, the 7 wastes have been referred to using different terms, in a different order and indeed with substitutions. It is common for example to see 'Rework' instead of 'Defects'. Also, academics and business thinkers have gradually expanded the seven wastes to include things such as 'unnecessary space' and 'latent skill' - the waste caused (or unnecessary cost incurred) when the person performing the task is over-qualified.

There is however, as far as I am aware, no new ‘definitive’ list of wastes that has established itself as clearly and prominently as the original 7 wastes, nor indeed should there be with the ever changing work environment. Who could have predicted back in 1948, when Taiichi Ohno started to develop the Toyota Production System (from which the 7 wastes sprang) that 'surfing the web' would now be regarded as one of the most significant wastes there is!

The 7 Types of Waste Explained

1. Transportation

Each time a product is moved it stands the risk of being damaged, lost, delayed, etc. as well as being a cost for no added value. Transportation does not make any transformation to the product that the consumer is willing to pay for.

2. Inventory

Inventory, be it in the form of raw materials, work-in-progress (WIP), or finished goods, represents a capital outlay that has not yet produced an income either by the producer or for the consumer. Any of these three items not being actively processed to add value is waste.

3. Motion

In contrast to transportation, which refers to damage to products and transaction costs associated with moving them, motion refers to the damage that the production process inflicts on the entity that creates the product, either over time (wear and tear for equipment and repetitive strain injuries for workers) or during discrete events (accidents that damage equipment and/or injure workers).

4. Waiting

Whenever goods are not in transport or being processed, they are waiting. In traditional processes, a large part of an individual product's life is spent waiting to be worked on.

5. Over-processing

Over-processing occurs any time more work is done on a piece other than what is required by the customer. This also includes using components that are more precise, complex, higher quality or expensive than absolutely required.

6. Over-production

Over-production occurs when more product is produced than is required at that time by your customers. One common practice that leads to over-production is large batch production, as often consumer needs change over time, resulting in some of the batch being wasted.

Over-production is considered by some to be the worst waste because it hides and/or generates all the others. Over-production leads to excess inventory, which then requires the expenditure of resources on storage space and preservation, activities that do not benefit the customer.

7. Defects

Whenever defects occur, extra costs are incurred reworking the part, rescheduling production, etc. This results in increased labour costs, more time in 'work-in-progress' etc. In practice defects can sometimes double the cost of one single product. This should not be passed on to the consumer and should be taken as a loss.

How to Identify the 7 Wastes in your Organisation

Of course generally the reason for wanting to understand what the 7 wastes are, is in order to identify them and reduce them in your organisation.

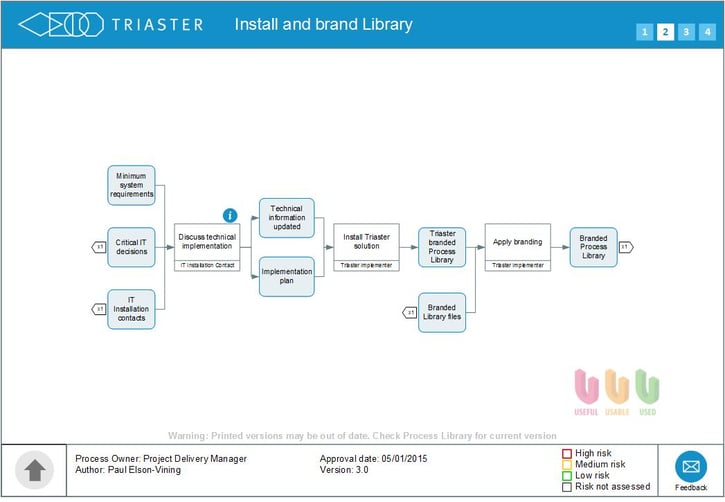

A common way to identify waste is to capture your processes in a process map - identifying all the inputs and the activities which transform then to outputs/deliverables in diagrammatic form. For more information on process mapping please read this article: What is Process Mapping, Who Does it and Why Use it?

Once the activities have been identified, they can be examined to see if they contain any of the 7 wastes as defined above.

What are Activities and Deliverables?

Activities are the things we do, they cost money, take time, require management, computer systems, machinery, training investment and so on.

Deliverables on the other hand are the consequence of performing Activities; Deliverables are produced once the Activities are complete and because the Activities were performed.

Only an Activity can be thought of as wasteful, never Delivery. Delivering the wrong things is assuredly wasteful, but that should in fact be thought of as, 'performing the wrong Activities'.

But how can you use this knowledge to cut out wasteful processes in your organisation?

How to Cut Out Waste in your Organisation

Once you have separated Activities from Deliverables in your process documentation, capturing waste becomes a relatively simple challenge of interrogating the Activities in your processes, and identifying any of the 7 forms of waste.

This process can be augmented by the value-stream mapping approach which asks the question, 'is this Activity value adding, non-value adding or necessary non-value adding?' This is a key question to ask, as some activities which might at first glance seem wasteful are necessary for health and safety, quality or accreditation reasons. For more on this, please read the article: Reconciling Sarbanes-Oxley Compliance and Process Improvement which answers the question, 'How do we ensure that improvements to processes to remove waste do not accidently remove the controls needed for Sarbanes-Oxley (SOx), other regulatory frameworks or standards, such as the Financial Conduct Authority (FCA), or ISO, compliance?'

The waste identified can initially be displayed through data driven visualisation, as explored in this article: Business Improvement Techniques: How to Display Waste Within a Process and then the process can be improved to reduce and if possible eliminate wasteful activities.

Free Process Mapping Software

Triaster has been working in the Process Mapping, Process Improvement and Business Process Management space for over 25 years. During that time we have developed a number of process improvement software tools, which our customers use to identify wasteful activities and improve their business processes.

Our drag and drop process mapping software, Process Navigator is free - so downloading it is a great way to start improving your business efficiency.

Related Articles:

Related Articles:

The 7 Waste Monsters That Kill Business (Video)

10 Ways to Stop Wasting Money and Increase ROI (Video)

What is Process Mapping, Who Does it and Why Use it?

Related White Papers:

The Ultimate Guide to Business Process Mapping

The Complete Guide to Continuous Improvement in Business

This is an updated and refreshed edition of an article originally written in 2017.

Written by Michael Cousins

Mike founded Triaster in 1994. A thought leader in business improvement, he has led Triaster ever since, spearheading its development of beautifully engineered business improvement software, that is both full of the functionality required by business analysts and that end users find really easy to use.